As I was playing with PIC16F1454, I came to the point where some configurability would be in order. You know how it goes with PIC microcontrollers - just write it in EEPROM and you’re good. Unless there is no EEPROM like there is none for PIC16F1454.

Never mind, I had this issue before, so I can just copy my own code (ab)using program memory for the same purpose. Guess what? There are some issue with this too.

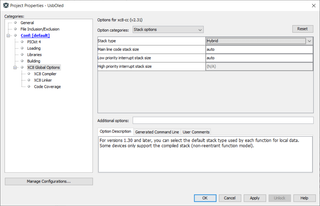

The first of all my old code was for different microprocessor. While principle is the same, it’s not an exact match. The second reason was changes to XC8. My old code doesn’t properly compile on XC8 2.00 - they changed how location is defined. The third (and the last) reason is high-endurance flash that PIC16F1454 supports. Unlike normal flash that’s rated for 10K writes, last 128 of this PICs program memory is rated to 100K. Albeit 10K is nothing to frown about, 100K is much nicer - especially if I end up changing data a lot.

Second and third reason share the same fix. Memory definition looks like this:

#define _SETTINGS_FLASH_RAW { 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0 }

#define _SETTINGS_FLASH_LOCATION 0x1FE0

const uint8_t _SETTINGS_PROGRAM[] __at(_SETTINGS_FLASH_LOCATION) = _SETTINGS_FLASH_RAW;

This will use the last 32 bytes, starting at 0x1FE0. This address is conveniently 32 bytes before end, falling without issues within “the last 128 bytes” high-endurance category. Now, if you need more memory, just make the array bigger and move it more forward. Just remember to do so in 32-byte increments as this is the block size for flash erase operation. If you don’t reserve all that memory, you might end up erasing your code and we wouldn’t want that. I personally never had need for more than 32 bytes of memory (i.e. one flash page) but your use case might differ.

All settings can be held in structure. Here I will have two settings - Address and DisplayHeight:

typedef struct {

uint8_t Address;

uint8_t DisplayHeight;

} SettingsRecord;

SettingsRecord Settings;

To read these settings, we just need to copy our reserved data (seemingly in _SETTINGS_FLASH_RAW variable) into the structure:

uint8_t* settingsPtr = (uint8_t*)&Settings;

for (uint8_t i = 0; i < sizeof(Settings); i++) {

*settingsPtr = _SETTINGS_PROGRAM[i];

settingsPtr++;

}

Writing is a two step process. It starts by erasing the WHOLE 32-word/byte block. Following that, we get to write each byte separately:

bool hadInterruptsEnabled = (INTCONbits.GIE != 0);

INTCONbits.GIE = 0;

PMCON1bits.WREN = 1;

uint16_t address = _SETTINGS_FLASH_LOCATION;

uint8_t* settingsPtr = (uint8_t*)&Settings;

PMADR = address;

PMCON1bits.CFGS = 0;

PMCON1bits.FREE = 1;

PMCON2 = 0x55;

PMCON2 = 0xAA;

PMCON1bits.WR = 1;

asm("NOP"); asm("NOP");

for (uint8_t i = 1; i <= sizeof(Settings); i++) {

unsigned latched = (i == sizeof(Settings)) ? 0 : 1;

PMADR = address;

PMDATH = 0x3F;

PMDATL = *settingsPtr;

PMCON1bits.CFGS = 0;

PMCON1bits.LWLO = latched;

PMCON2 = 0x55;

PMCON2 = 0xAA;

PMCON1bits.WR = 1;

asm("NOP"); asm("NOP");

address++;

settingsPtr++;

}

PMCON1bits.WREN = 0;

if (hadInterruptsEnabled) { INTCONbits.GIE = 1; }

The first and last step is dealing with interrupts. During write interrupts must be disabled. Code will disable them before writing and re-enable them afterward if needed.

Erase is easy enough. Just set FREE bit in the PMCON1 register followed by magic incantation (0x55, 0xAA, WR=1) and wait for a millisecond or two. Do note that NOP instructions are mandatory due to how self-writing program memory works. It’s one of the rare instances where NOP actually serves a purpose in C code.

To write data, process is close enough. Load all the bytes you wish to write using PMADR and PMDAT registers to set address and data. All bytes except the last will have LWLO bit set and will just cause loading of data into latches. The last byte must have LWLO cleared, signaling we’re done with writing. After a millisecond or two, bytes are done.

Two things are slightly curious there. The first one is setting of PMDATH to 0x3F. This value is actually the same as for erased cell and this just means we’re not changing it’s value. Note that upper byte is not the part of high-endurance flash and only 6-bit value (words are 14-bits on this PIC). Thus we really shouldn’t use it. The second strange decision is to start loop from 1 instead of the more conventional 0. This is so that we can determine if we’re at the last byte without substracting one.

In any case, this is all you need to make your program memory work as a storage for your settings.

PS: Procedure is the same on PIC16F1454, PIC16F1455, PIC16F1459, and probably quite a few more.

PPS: Whole code is available in Git repository.

PPPS: There is quite useful application note from Microchip (AN1673A) dealing with high-endurance flash. Their code uses similar but slightly different approach. If you don’t like this code, maybe theirs will tickle your fancy.