Digi-key

My work brought me to USA for couple of months now. Since I cannot live without solder-smell I had few electronics order here and there. Something from SparkFun, something from Mouser, something from others…

I always pay with my credit card (issued in Croatia) and I had no problem what-so-ever. That is until I tried Digi-Key.

I filled-out the order, payed with credit card and went to sleep. In morning I got:

_Thank you for your order. However, before I am able to proceed, I do need some additional information.

You are shipping to the USA and billing to Croatia. Are you shipping to a freight forwarder? If so, please provide name and website as this can change the tax status of the order. Would you always ship to this address?

Please verify the phone number for the shipping address and for the Croatia address.

Please also provide more information on the application of the parts. What type of application will this product be used in? Example: automotive, medical, telecommunications, etc_

This is annoying. If I say that I want it shipped to USA, why is there questioning of that decision? All other stores could live with me moving to another country. Why can’t Digi-Key?

And this is not the first mail I got from them, they already confirmed my address once. Will I go through same dance every time?

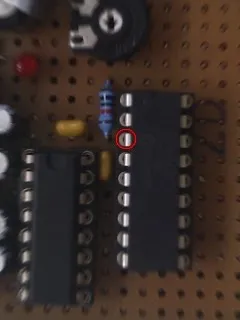

Why do I need to tell what I am using this chips for? Cannot somebody order chips without any particular project in mind other than to have fun?

It might not seem like a huge issue, but I hate this “customer must be wrong approach”. It forces me to babysit my e-mail after sending order and makes everything late by one day at least.

P.S. They did send package, but only after calling my hotel and checking me out. I really appreciate being called liar…